Control Banding Approaches for Welding: A Practical Method to Protect Workers’ Health

Sponsored by Chemscape Safety Technologies

Prior to the classification of “welding fumes” as a Group 1 carcinogen by the International Agency for Research on Cancer, industrial hygiene professionals’ traditional assessment method would estimate the relative carcinogenicity of the base metal and electrodes to determine control approaches appropriate for welding tasks. But not every small or medium-sized business with welding activities has the resources to employ a professional hygienist. Traditional assessment methods can incur delays waiting for sampling results and recommendations while workers continue to be overexposed.

Control banding simplifies exposure controls and offers a pragmatic approach to assessing risks and recommending controls, particularly when occupational exposure limits for aggregate welding fumes or measurement methods are unavailable.

Follow the Hierarchy of Controls When Reviewing Your Welding Operations

Using a consistent, objective system to identify engineering and administrative controls is valuable. For example, a work site with welding operations needs a control approach for each task. Control banding can simplify the identification of control approaches. The carcinogenic nature of welding or thermal cutting fume excludes any control approaches based on natural or dilution ventilation.

Engineering controls such as local exhaust ventilation (LEV) can reduce fume exposures if used correctly (that is, positioned 1 to 1.5 hood diameters from the arc) and routinely measured for effectiveness. LEV should be part of the solution but not the basis of a control approach. Even if LEV does not eliminate welding fume at the source, it can enhance natural ventilation to reduce fume exposure to coworkers in the shop or in the immediate vicinity outdoors.

Control approaches for welding need to start with containment. Containment of the process is where emissions are captured at the source. The containment needs to create a pressure around the isolated source so that clean air moves into the contaminated zone. This scenario is ideal but may not be practical or available outside of dedicated, state-of-the-art manufacturing facilities. Containment of the worker is another way of protecting welders. In this containment, the worker is surrounded by clean air under positive pressure, as in an isolation room. Most welding necessitates the worker being within arm’s length of the work, which makes an isolation room unrealistic; however, isolating the worker’s breathing zone is not.

Use of a powered, air-purifying respirator (PAPR) is intended to create a containment level of protection for the welder during welding and thermal cutting processes. Because use of a PAPR is not true containment of the contaminant, the control scheme must include protection for other workers, contractors, or visitors. Increased ventilation or LEV, restricted work areas, decontamination practices, and PPE are also part of the control scheme.

Control Banding Welding Processes

Another aspect of welding work that facilitates control banding is the classification of welding processes into two categories: low-fume emitters and high-fume emitters. In high-fume emission processes, there is no physical barrier between the arc and the welder, and the welding process uses the consumable as the electrode. Thermal cutting processes are high fume by default. Examples of thermal cutting processes are shielded metal arc welding (SMAW, also called manual metal arc welding or MMA), flux-cored arc welding (FCAW), gas metal arc welding (GMAW), arc cutting, and arc gouging. In contrast, low-fume emission processes include gas tungsten arc welding (GTAW or “TIG”), which does not use a consumable electrode; and submerged arc welding (SAW) and resistance welding (RW, also known as “spot welding”), in which a physical barrier (a mound of flux or parts being welded) is placed between the arc and welder.

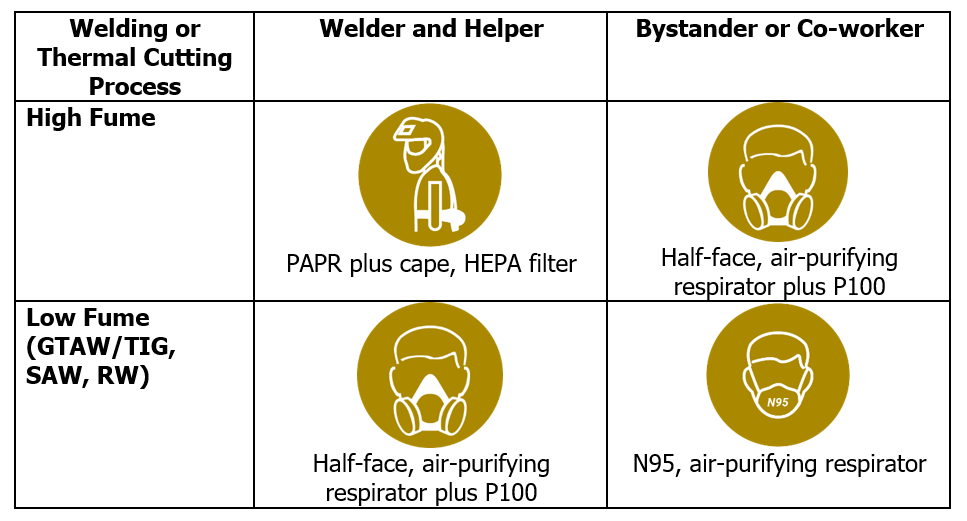

By separating the exposed population into two groups and the exposure into two categories, control banding simplifies exposure control into four approaches:

- High fume emitting process: welder and helper require a PAPR with cape and HEPA filter.

- High fume emitting process: coworkers or bystanders in the shop or in the immediate vicinity outdoors require a half-face, air-purifying respirator (HFAPR) with a P100 filter.

- Low fume emitting process: welder and helper require an HFAPR with a P100 filter.

- Low fume emitting process: coworkers or bystanders in the shop or in the immediate vicinity outdoors require an N95 respirator.

In conclusion, while control banding does not replace traditional IH assessment methods for welding, it is a practical method to protect workers’ health.

More information about Chemscape Safety Technologies and its CHAMP product is available on the company website.

Resource:

AIHA: Welding Health and Safety: A Field Guide for OEHS Professionals, 2nd edition (2021).

Comments

There are no submissions.