The term mining is used in the broad sense to include the extraction of minerals occurring naturally: solids, such as asbestos, coal, and ores; liquids, such as crude petroleum; and gases such as natural gas. The term mining is also used in the broad sense to include quarrying, well operations, milling (e.g., crushing, screening, washing, flotation), and other preparation customarily done at the mine site, or as a part of mining activity.

Exploration and development of mineral properties are included. Services performed on a contract or fee basis in the development or operation of mineral properties are classified separately but within this division. Establishments that have complete responsibility for operating mines, quarries, or oil and gas wells for others on a contract or fee basis are classified according to the product mined rather than as mineral services.

Mining operations are classified, by industry, on the basis of the principal mineral produced, or, if there is no production, on the basis of the principal mineral for which exploration or development work is in process. The mining of culm banks, ore dumps, and tailing piles is classified as mining according to the principal mineral product derived.

Crushing, grinding, or otherwise preparing clay, ceramic, and refractory minerals; barite, and miscellaneous nonmetallic minerals, except fuels, not in conjunction with mining or quarrying operations, are classified in Manufacturing, Industry 3295. Dressing of stone or slabs is classified in Manufacturing, Industry 3281, whether or not mining is done at the same establishment.

Mining provides iron and copper for making airplanes, refrigerators. Mines also supply salt for food, gold, silver, and diamonds for jewelry; and coal for fuel. Miner extract uranium for nuclear energy, stone for buildings, phosphate for fertilizers, and gravel for roads. Some minerals can be mined more cheaply than others because they are found at the earth’s surface. Some minerals lie beneath the surface and can be removed only by digging deep underground. Other elements are found in oceans, lakes, and rivers across the globe.

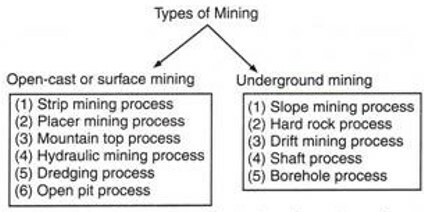

There are basically two types of mining:

Surface Mining (Quarrying)

In this type of mining, the minerals or rocks that are to be mined are exposed at the surface or very close to the surface. To extract the materials, earlier the miners used to dig an open-pit on the surface and then dig out the materials. But nowadays, giant earthmovers remove the topsoil and the rocks and the material is extracted. In this context, a quarry is a type of open-pit mine in which dimension stone, rock, construction aggregate, riprap, sand, gravel, or slate is excavated from the ground There are different types of surface mining processes:

- Surface Mining process: As the name suggests the surface of the earth is stripped. In this process, the soil and rocks that lie above are removed generally by heavy machinery and then the material is extracted. This type is possible only when the targeted materials are relatively near the surface. The mineral generally extracted is coal or some kinds of sedimentary rocks.

- Placer mining process: In this process, alluvial deposits in sand or gravel are extracted. This process does not involve the usage of any sort of heavy materials and can be considered relatively easy when compared to others. Generally, gold and other gemstones are mined in this process.

- Mountain top process: This process involves blasting off the top of mountains expose the coal below it. This process is relatively new.

- Surface Mining process: In this process, high-pressure water jets are used to dislodge rocks and minerals. During earlier times gold was found in an easier way by this method. However, this process has been discontinued due to environmental concerns.

- Dredging process: It is the process of underwater excavation by deepening a water body. In this method, sediments and other substances are removed from harbors, rivers, and other water bodies, and minerals are extracted.

- Open-pit process: The easiest and the cheapest way to mine materials that are close to the surface, large open holes are dug in the ground. Sometimes, explosives are used to get large blocks of rocks out of the way.

Underground Mining

Quarrying can also include the underground quarrying for stone, such as Bath stone. Regarding underground mining, there are five processes.

- Slope mining process: A type of underground mining, slopes are made into the ground and the desired material is accessed. This is done when the minerals are located far enough, and surface mining cannot be employed to reach it. Generally, coal is mined in this way.

- Hard rock process: Here tunnels deep in the ground are dug sometimes with dynamite or large drills. The tunnels are supported by pillars through which miners can move about. Tin, lead, copper, silver, gold, etc. are mined with this process. This is a type of mine that comes to our minds when we think of the industry.

- Drift mining process: This process is carried out when the material is situated sideways of a mountain. The materials are easier to access, and the mouth is made slightly lower than the resource area so as to allow gravity to pull down the materials easily. Generally, coal or iron ore is mined through this process.

- Shaft process: The deepest form of underground mining, is done by excavating a vertical passageway deep down. The materials to be extracted are situated deep inside and elevators are used to take the miners up and down. These tunnels are made airy for miners to work without any problems. Generally, coal is mined in this process.

Borehole process: Using a drill a deep hole is dug and a high-pressure water jet is used to force the materials up the hole. Sand, galena, gold, etc. are mined by this process.

Figure 1: OHTA Mining Training Materials

Some occupational health hazards associated with this industry include asbestos, arsenic, nickel, lead, cadmium, manganese, platinum, vanadium, cobalt, mercury, chromates, radon gas, air pollution for diesel exhaust emission from transport and operate equipment, noise pollution from rock drills to explosives, and carbon monoxide (white damp) and sulfur dioxide gas (stink damp) from operating equipment, polymeric chemicals in the coal mine, oxides of nitrogen from blasting, methane gas (firedamp), oxygen deficiency (black damp), whole-body vibration driving rock trucks and pneumatic drilling, musculoskeletal disorders from heavy lifting, awkward postures and stress, UV radiation, and thermal extremes working outdoors. Some risks are greater during the metallurgical process than the mining of ore. For example, cyanide is a solvent in gold and copper hydrometallurgical processes. Hydrofluoric acid is used to analyze core samples while exploration drilling. There are psychosocial, barometric pressure underground, and biological hazards.

Naturally Occurring Radioactive Material (NORM) might be released from oil and gas formations. Workers at risk of exposure include those who handle pipes and equipment that might have been contaminated with NORM. Sludge, drilling mud, and pipe scales, for example, often contain elevated levels of NORM, and radioactive materials might be moved from site to site as equipment and materials are reused. Disposal, reuse, and recycling of NORM can cause worker exposures.

Mining pollutes the groundwater. Sulfur, usually present as an impurity in many ores is known to get converted into sulfuric acid through microbial action, thereby making the water acidic. Sulfur is one reacts with water and oxygen to form sulfuric acid which leaks out from the mine. This is known as acid mine drainage. The acid mine drainage often contaminates the nearby streams and lakes. It severely degrades water quality and can kill aquatic life and make water virtually unusable. Radioactive substances like uranium, heavy metals also contaminate the water bodies and kill aquatic animals.

In order to separate and purify the metal from other impurities in the ore, smelting is done which emits enormous quantities of air pollutants. Oxides of sulfur, arsenic, cadmium, and lead, etc. enter the atmosphere near the smelters and the public suffers from several health problems. The ground and noise vibrations are produced during mining operations such as drilling and blasting, movement of mining equipment’s like shovels, dumpers, drills, dozers, rippers, etc. Miners working in different types of mines suffer from respirable diseases such as asbestosis, silicosis, black lung.

The following table of profiles represents only the potential occupational health concerns related to the entire mining industry based on the type of mining, job task or work activity, and any related MSHA standards for regulatory compliance. The information presented herein does not indicate or suggest a relative risk of exposure based on the location within the table nor provides any exposure information. Health risks associated with fatigue, working long hours, stress living away from home, and other psychosocial disorders are not addressed. The focus of this information is to provide guidance to understand the occupational health hazards from chemical substances, physical and biological agents, radiological, ergonomic, and environmental hazards from exposure to plants and animals. The potential occupational health exposures were contrived from the OSHA Integrated Management Information System database between 1984 to 2020.

Miners are at risk of developing a lung disease called pneumoconiosis because of their regular exposure to airborne respirable dust, and miners with five or more years' mining experience who are exposed to exhaust from diesel engines have an increased risk of dying from lung cancer. Pneumoconioses (meaning dusty lung) can cause impairment, disability, and premature death.

The two main types of pneumoconioses that affect miners are coal workers’ pneumoconiosis (CWP), commonly called black lung, and silicosis. CWP is associated with coal mining, but silicosis can affect workers in many types of mines and quarries, including coal mines. Medical treatment cannot cure these diseases, so preventing them – through controlling respirable dust exposure – is essential.

Exhaust from diesel engines has the potential to produce symptoms typical of asthma, and diesel exhaust exposure may contribute to other respiratory symptoms such as irritation of the nose, inflammatory changes in airways, and lung function decline. Other respiratory diseases, such as chronic obstructive pulmonary disease (COPD), may also occur in miners separately from, or in addition to, pneumoconiosis.

NIOSH, through the Coal Workers’ Health Surveillance Program (CWHSP), provides underground coal miners with an opportunity to have a chest x-ray on a periodic basis (approximately every five years) throughout their careers. The Respiratory Health Division of NIOSH manages this program and compiled data since 1970 to track the prevalence of CWP in coal miners. As shown in the figure below, the prevalence of examined miners with 25 or more years of mining experience that were diagnosed with CWP dropped from approximately 33% in the early 1970s to less than 5% by the late 1990s. Since that time, CWP prevalence has increased to over 10% for the longest-tenured miners. NIOSH recently reported an unprecedented number of miners (416) were diagnosed with progressive massive fibrosis (PMF), which is the most severe form of CWP, when examined at three black lung clinics in Virginia. Through a special CWHSP program, NIOSH examined over 2,200 surface miners from 2010-2011 and found 46 with CWP, 12 of which had PMF.

From 2007 through 2016, CWP has been the underlying or contributing cause of death for 4,118 miners and a total of 75,178 miners from 1970 through 2016. More than $47.168 billion dollars in federal compensation has been paid to miners and their families from 1971 through 2019 for claims filed under the Black Lung Benefits Act. Silicosis is not tracked as regularly or thoroughly as CWP but available historic data from the 1990s shows that over 23% of reported silicosis deaths were attributed to mining. Also, the change in disease profile for miners diagnosed with pneumoconiosis suggests that US coal miners are being exposed to more crystalline silica than in the past. This data shows a substantial increase over the last four decades in r-type opacities (associated with silicosis lung pathology) in the chest radiographs of miners in the Central Appalachian region. The Diesel Exhaust in Miners Study of more than 12,000 miners showed a significant increased risk of dying from lung cancer among miners who never worked underground. This risk increased as the miners’ exposure to respirable elemental carbon – representing diesel exhaust – increased.

Industries in the oil and gas extraction subsector operate and/or develop oil and gas field properties. Such activities may include exploration for crude petroleum and natural gas; drilling, completing and equipping wells; operating separators, emulsion breakers, desilting equipment, and field gathering lines for crude petroleum and natural gas; and all other activities in the preparation of oil and gas up to the point of shipment from the producing property. This subsector includes the production of crude petroleum, the mining and extraction of oil from oil shale and oil sands, and the production of natural gas, sulfur recovery from natural gas, and recovery of hydrocarbon liquids.

In the non-industrial world within developing countries, Artisanal and Small-scale Gold Mining (ASGM) involves a complex interplay of social, economic, technological, environmental, and health factors that can vary considerably across local and national contexts. This complexity makes it difficult to establish uniform definitions. Artisanal and small-scale gold mining is defined in the Minamata Convention on Mercury as “gold mining conducted by individual miners or small enterprises with limited capital investment and production” (United Nations Environment Program, 2014). The International Labour Organization describes artisanal and small-scale mining as “…labor-intensive, with mechanization being at a low level and basic” (Jennings, 1999).

Building on this description, the World Bank’s Communities, Artisanal, and Small-Scale Mining (CASM) initiative elaborates on the economic and social effects of artisanal and small-scale mining work as “… largely a poverty-driven activity, typically practiced in the poorest and most remote rural areas of a country by a largely itinerant, poorly educated populace with little other employment alternatives” (World Bank, 2013). Most definitions of artisanal and small-scale mining share the following characteristics: an informal work sector, limited use of mechanical tools, labor-intensive work, low capital and productivity, deposit exploitation, and limited access to land. (Hentschel, Hruschka and Priester, 2003; Mining, Minerals and Sustainable Development, 2002).

These characteristics illustrate the cycle of poverty that can exist in artisanal and small-scale mining communities, particularly where inefficient mining and processing techniques yield a small quantity of a product and low profit (Barry, 1996). Further compounding this cycle are the health and environmental hazards associated with this type of work. Artisanal and small-scale gold mining is carried out in over 70 countries by approximately 10-15 million miners including approximately 4-5 million women and children (United Nations Industrial Development Organization, 2006b; Telmer, and Veiga, 2009). While ASGM activities occur all over the world, they are most prevalent in South America, Africa, and Asia (Hinton, 2006; Böse-O’Reilly, World Health Organization, 2013a, 2014). ASGM usually comprises the following steps:

- Extraction: Miners exploit alluvial deposits (river sediments) or hard rock deposits. Sediment or overburden is removed, and the ore is mined by surface excavation, tunneling, or by dredging (in the case of alluvial mining) (United Nations Environment Program, 2015).

- Processing: In this step, the gold is liberated from other minerals. The methods used for processing can vary depending upon the type of deposit. Gold particles in alluvial deposits are often already separated and require little mechanical treatment. While for hard rock deposits, crushing and milling are required. Primary crushing can be done manually, for example using hammers, or with machines. Mills are then used to grind the ore into smaller particles and, eventually, fine powder.

- Concentration: In some cases, gold is further separated from other materials by concentration. Different methods and technologies (e.g. sluices, centrifuges, vibrating tables, etc.) may be used to concentrate the liberated gold. The density of gold compared with other minerals in the ore is often higher. Therefore, many techniques utilize gravity for concentration (United Nations Environment Program, 2012).

- Amalgamation: Elemental mercury is used to obtain a mercury-gold alloy called an “amalgam” (roughly equal parts mercury and gold). There are two main methods used in ASGM for amalgamation: whole ore amalgamation and concentrate amalgamation.

- In whole ore amalgamation, elemental mercury is added with little prior comminution and concentration. Large quantities of mercury are often used (between 3-50 units per unit of gold recovered) and most is released as waste into the mine tailings because of the resulting inefficiency of this process (Sousa et al., 2010; United Nations Environment Program, 2015). For these reasons, whole ore amalgamation is included in Annex C of the Minamata Convention on Mercury as an “action to eliminate” (United Nations Environment Program, 2014).

In concentrate amalgamation, the mercury is added only to the smaller quantity of material (“concentrate”) that results from the concentration step. As a result, considerably less mercury is generally used. Excess mercury can also be recovered. (United Nations Environment Program, 2015).

- Burning: The amalgam is heated to vaporize the mercury and separate the gold. In “open burning”, all of the mercury vapor is emitted into the air. Open burning of amalgam or processed amalgam is, therefore, also considered an “action to eliminate” in Annex C of the Convention. The gold produced by amalgam burning is porous and referred to as “sponge gold” (United Nations Environment Program, 2015).

- Refining: Sponge gold is further heated to remove residual mercury and other impurities. Throughout this work process miners as well as others living and working nearby, ASGM processing sites are exposed to a variety of environmental and occupational health hazards that will be discussed in later sections. Methods and technologies used in the ASGM process can vary significantly from place to place. Environmental and occupational health hazards, and populations affected by those hazards, can also vary. Therefore, context-specific responses are needed.

Hundreds of thousands of people work in oil and gas extraction in the United States; ensuring their health and safety is a major concern for employers, regulators, trade associations, industry groups, and local communities. Work in this industry involves physical labor, 24/7 operations, heavy machinery, hazardous chemicals, often remote locations, and all-weather conditions, resulting in an elevated risk of physical harm and the need for special protections to reduce this risk.

Oil and gas well drilling and servicing activities involve the use and production of potentially hazardous materials. OSHA, the National Institute for Occupational Safety and Health (NIOSH), and industry and safety groups continue to evaluate the type and extent of chemical and other health hazards across the industry.

During the 2000s, there has been an increase in hydraulic fracturing operations in the oil and gas extraction industry. NIOSH has initiated a field effort to assess chemical exposures in this industry. NIOSH identified exposure to airborne respirable crystalline silica as a health hazard to workers conducting some hydraulic fracturing operations.

Potential health hazards are highlighted below.

- Diesel Particulate Matter

- Fatigue

- Hazardous Chemicals

- Hydrocarbon Gases and Vapors (HGVs) and Low Oxygen Environments

- Hydrogen Sulfide

- Naturally Occurring Radioactive Material (NORM)

- Noise

- Respirable Crystalline Silica

- Temperature Extremes

While fatal work injuries have been well studied, less is known about other health hazards. Since 2010, the NIOSH has conducted field studies in partnership with the industry to better identify chemical exposure hazards. The major hazards identified through these studies were respirable crystalline silica dust during hydraulic fracturing and exposure to hydrocarbon gases and vapors when manually sampling oilfield tanks:

Respirable Crystalline Silica Dust – Large quantities of silica sand are used during hydraulic fracturing. Loading and transferring this sand at the well site generates respirable-sized silica dust particles in concentrations that may exceed occupational exposure limits. Other processes that generate silica dust at the well site may include drilling with air and mixing cement to construct or plug a well. Inhalation of silica dust is associated with silicosis, other respiratory issues, and potentially other adverse health effects.8 NIOSH recommends monitoring worker exposure and, when necessary, controlling exposure with engineering controls and improvements to work practices and procedures. New OSHA standards for silica take effect on June 23, 2021, for hydraulic fracturing operations, which are expected to implement engineering solutions that limit silica exposure.

Hydrocarbon Gases and Vapors – Tanks holding crude oil or produced water are common in the oilfield. These tanks may be manually measured and sampled, which may expose workers to dangerous levels of hydrocarbon gases and vapors given off by these liquids. Between 2010 and 2014, at least nine oilfield workers died as a result of this exposure. In response, NIOSH and OSHA published a hazard alert related to manual tank gauging, which recommends using alternative systems to measure and sample tank fluids without opening the tank hatch, as well as training workers and not permitting employees to inspect tanks alone.

Other hazards include hydrogen sulfide gas (which occurs naturally in oil and natural gas and is extremely hazardous when inhaled); noise (from heavy machinery, for which OSHA sets maximum limits and required hearing protection13); and diesel exhaust (from drilling rigs and other equipment – while diesel exhaust is not specifically regulated, OSHA sets exposure limits for many of the most harmful air pollutants found in diesel exhaust).

Oilfield fluids contain a wide range of hazardous chemicals. While some can have immediate health effects (such as hydrogen sulfide gas, which can kill instantly at high concentrations), others may have longer-term effects (such as benzene, which is carcinogenic). However, few published studies exist that track the long-term health consequences of working in oil and gas extraction, making it difficult to draw conclusions about specific long-term health risks.

Photos courtesy of Getty Images.

Worker Exposure Profiles in Mining

To search within this table, "Control-F" on your keyboard will start a search in your web browser.